Introducing The Lambda768 Laser Marker

Automated Precision Marking

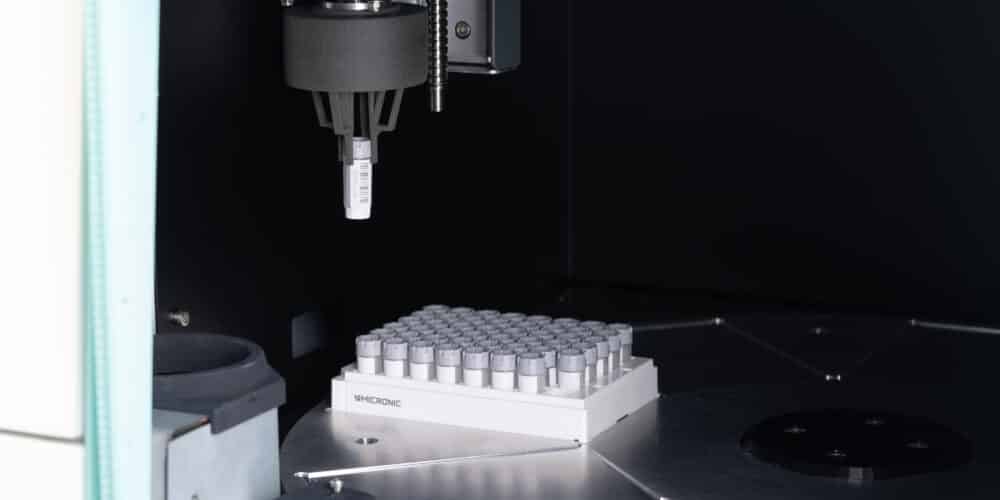

The Lambda768 meets laboratory demands for speed, precision, and reliability in tube marking. Processing up to 500 tubes per hour, it ensures high throughput. Its rotating platform marks multiple racks in a single run, streamlining workflows and providing valuable walk-away time. With a high-precision laser, the Lambda768 marks any laserable surface, including black, white, or colored. It engraves text, barcodes, batch IDs, logos, and shapes for permanent, clear tube identification.

High-Throughput Engraving

The system automates the marking of up to 8 ANSI/SLAS racks per cycle and accommodates 96-, 48-, or 24-well tube formats. Its robust construction ensures each marking is durable and resistant to chemicals, abrasion, and extreme temperatures ranging from -196°C to +100°C.

Seamless Automation and Compatibility

The Lambda768 can be easily integrated into automated laboratory systems. By removing the side panel, a robotic arm can access the platform directly, enhancing process automation. The unit supports tubes from major brands, including Azenta, Micronic, and LVL Technologies, ensuring broad compatibility and operational flexibility.

Sustainability and Cost Efficiency

Unlike traditional labeling methods, laser marking with the Lambda768 eliminates the need for consumables such as ink, labels, or stickers. This reduces both operational costs and environmental waste. The process produces no harmful emissions, making it a sustainable alternative to chemical-based marking systems.

Setting a New Standard

With its cutting-edge design, internal processing unit, and intuitive control interface, the Lambda768 Laser Marker by AFYS3G defines a new standard in laboratory marking. It combines accuracy, efficiency, and sustainability, ensuring laboratories can operate with maximum throughput and minimal manual intervention. Experience the future of sample identification, discover the Lambda768 Laser Marker now.